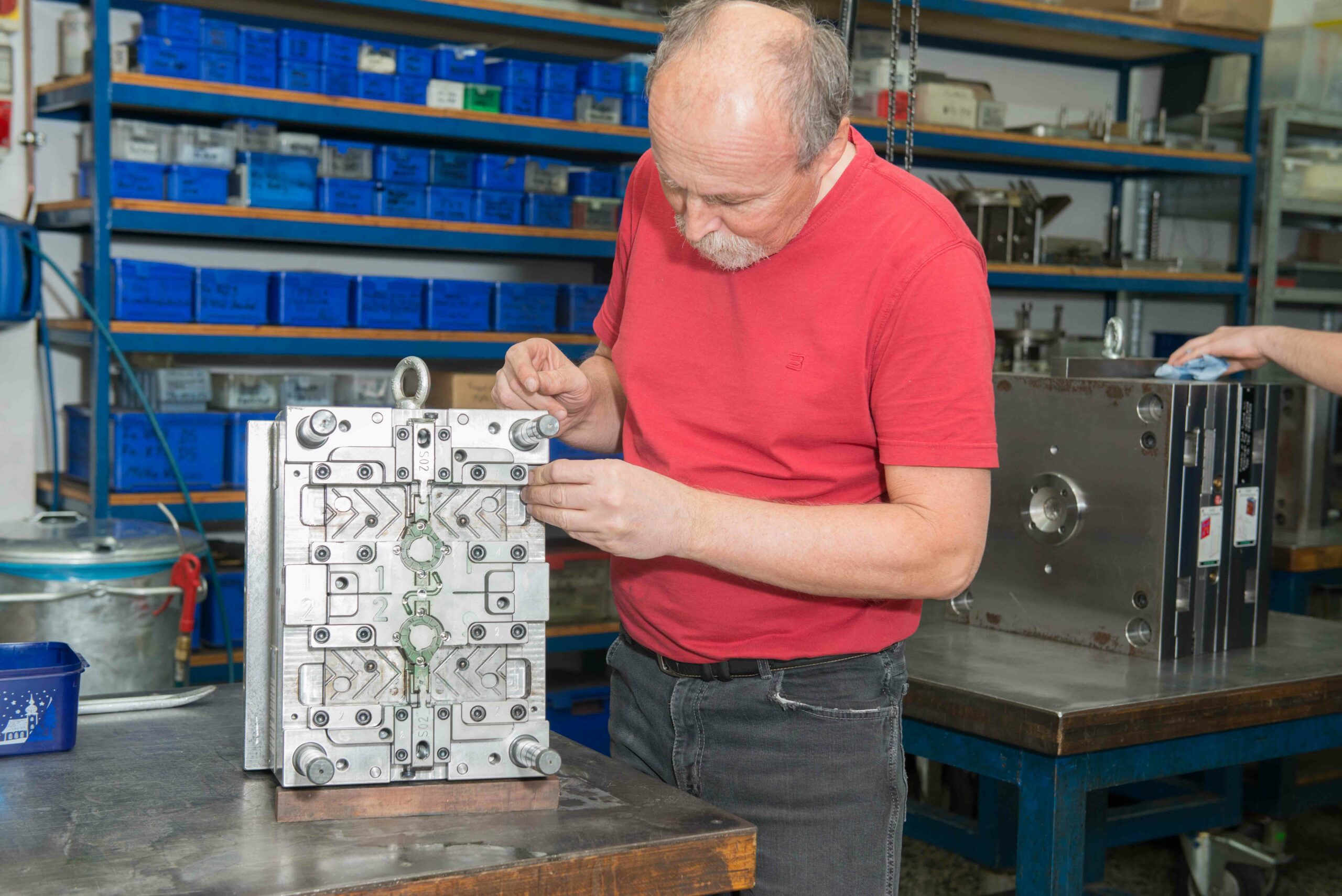

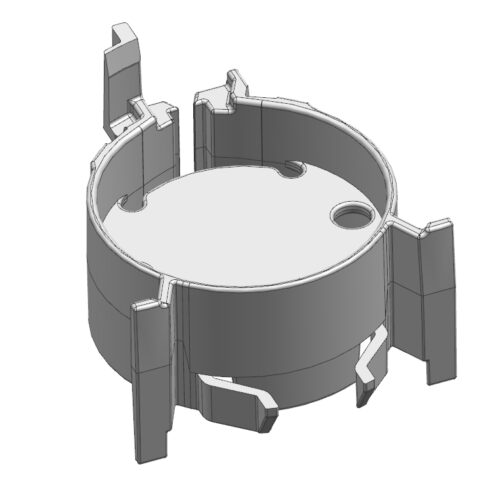

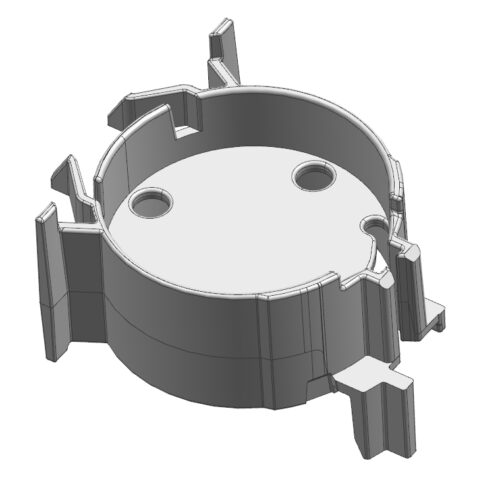

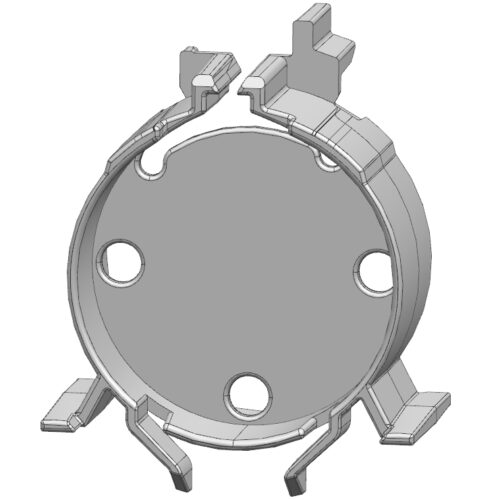

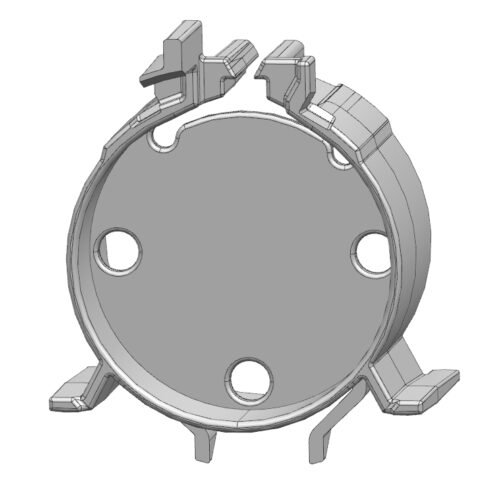

PBT and the horror of breaking! Bellows holder_pn = the continuation of the HK direct connection when using PBT. The bellows holder pn counts as a component of the pneumatic lifter in cisterns newly developed in 2019. The application requires this part be made of PBT. From the point of view of those responsible for technology in the Geberit Group, such a part can only be realized with a cold runner connection in the injection molding tool if one wants to avoid problems with breaking parts and thus complaints. Since the Geberit Pottenbrunn injection molding plant has had rather positive experiences with HK direct connections for PBT components over several years, there was a willingness to take a risk with this component, despite the group’s reservations about creating the tool required for the component with an HK valve gate direct connection. In order to bring this group’s wish to fruition, Miraplast issued a conversion guarantee for the mold to be realized with a cold runner connection, which would have become effective if the parts had demonstrably not met the requirements due to the HK direct connection.

PBT and the horror of breaking! Bellows holder_pn = the continuation of the HK direct connection when using PBT. The bellows holder pn counts as a component of the pneumatic lifter in cisterns newly developed in 2019. The application requires this part be made of PBT. From the point of view of those responsible for technology in the Geberit Group, such a part can only be realized with a cold runner connection in the injection molding tool if one wants to avoid problems with breaking parts and thus complaints. Since the Geberit Pottenbrunn injection molding plant has had rather positive experiences with HK direct connections for PBT components over several years, there was a willingness to take a risk with this component, despite the group’s reservations about creating the tool required for the component with an HK valve gate direct connection. In order to bring this group’s wish to fruition, Miraplast issued a conversion guarantee for the mold to be realized with a cold runner connection, which would have become effective if the parts had demonstrably not met the requirements due to the HK direct connection.

Since we would never have been able to build this mold with the approval of the group without this guarantee and that of the HK manufacturer, Miraplast played a significant role in the trouble-free and sprueless production of the tool. Operating inconspicuously, it provides us failure-free production hours and flawless parts!

On behalf of Geberit Pottenbrunn, I would like to express my thanks for their willingness to take risks and look forward to the next exciting projects!